rhizopur process

Reading time:The Rhizopur process is a process that has been patented for treating household wastewater and which is ideal for small communities. It combines a trickling filter with infiltration beds planted with reeds called rhizofilters. Considered separately, both are well-known technologies, the original nature of the Rhizopur system arising from the fact that it combines the two processes.

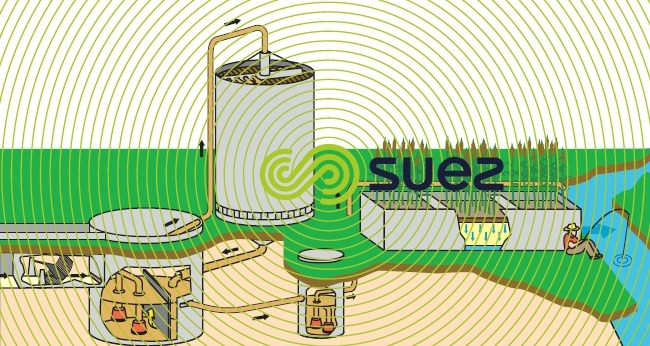

Figure 40 provides an overview of the water and sludge treatment system.

After it has undergone pre-treatment, water is fed into a lifting unit and distributed over the top of the 4 m high plastic-filled trickling filter. This first stage processes the dissolved and colloidal carbonaceous matter and, if applicable, applies nitrification.

The treated water-biomass mixture is routed to the rhizofilter stage by a pumping unit. The number of beds used will be three or multiples of three, for satisfactory bed supply and rest period management. In effect, a bed’s maturation time must be equal to twice the infeed time.

The filtering component consists of three layers of material whose granulometry increases from the top downwards: upper layer of sand, lower layers of gravel.

The plants set in the sand are reeds (phragmites australis) that tolerate the conditions prevailing in this type of environment. Their main role is the mechanical action of the rhizomes that ensure that the filtering medium permeability is maintained; these reeds are also used as bacteria anchoring support.

Sludge management is very simplified. The sludge and the liquid are fed onto the surface of the rhizofilters where they undergo a slow aerobic digestion process. A layer of approximately 25 cm of sludge accumulates each year for a system that is fed at full load. The layer must be removed when it becomes 1 to 1.5 m thick and this removal is carried out by a mechanised device. The layer’s final destination will depend on the local context.

A properly designed and dimensioned treatment system will satisfy discharge requirements in normal areas: COD < 125 mg · L–1, BOD < 25 mg · L–1 and suspended solids < 35 mg · L–1. Depending on site conditions, this system is capable of nitrifying nitrogen ammonia (temperature, loading applied …).

By virtue of its performances and characteristics (low labour requirement, low energy consumption, reduced and stabilised sludge output), this process is particularly suited to small treatment plants.

Bookmark tool

Click on the bookmark tool, highlight the last read paragraph to continue your reading later